Automation: Transforming Steel Production and Foundries

The integration of automation is revolutionizing the steel production and foundry industries. By leveraging advanced technologies, these traditionally labor-intensive sectors are achieving unparalleled efficiency, enhanced safety, and reduced environmental impact. This shift toward automation is driving innovation and sustainability across heavy industries.

How Automation is Revolutionizing Steel Production

Steel production is a multifaceted process that includes raw material handling, smelting, refining, and shaping. Automation has introduced groundbreaking advancements at every stage:

Streamlined Operations

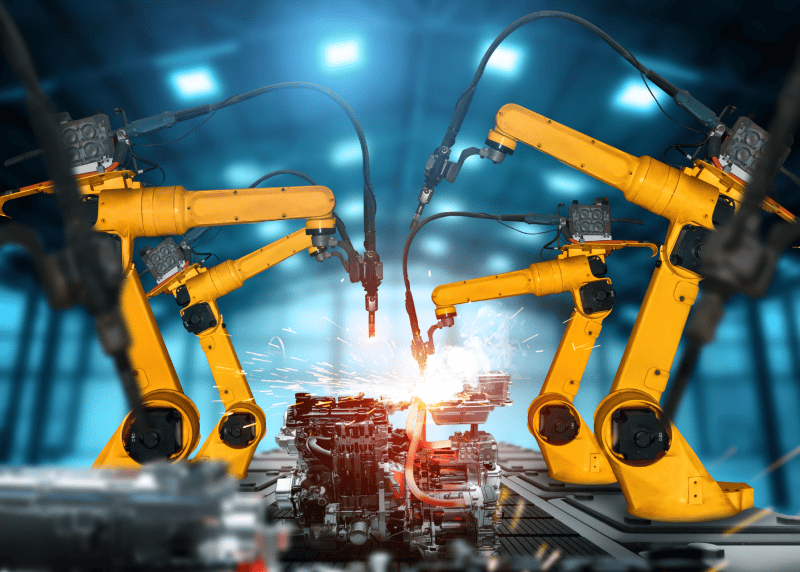

Automated systems, such as robotic arms and conveyor systems, ensure smooth material flow, reducing production delays. Automated hot billet shearing machines, for example, operate at high speeds, boosting throughput and minimizing downtime.

Enhanced Quality Control

With technologies like CNC machines, automation ensures precision and consistency in steel shaping. This minimizes errors and guarantees products meet strict quality standards.

Energy Efficiency

Smart equipment, such as automated furnaces, optimizes energy usage through real-time data analytics. These systems adjust fuel and temperature levels, reducing energy consumption and lowering operational costs.

Advancing Safety Standards in Foundries

Foundries, where molten metals and heavy machinery are prevalent, have significantly improved safety standards thanks to automation:

Safe Material Handling

Automation systems, including robotic grab buckets and lifting magnets, reduce human involvement in handling hazardous materials. This minimizes risks of injuries caused by molten metals and heavy loads.

Improved Ergonomics

By automating repetitive and strenuous tasks, such as pouring molten metal or moving castings, workers face fewer physical strains. Tools like hydraulic pushers and automated pouring systems ensure safer and more efficient workflows.

Real-Time Monitoring

Sensors embedded in automated equipment detect potential issues, such as overheating or mechanical failures. These systems enable predictive maintenance, reducing the likelihood of accidents and costly downtimes.

Data and AI: The Backbone of Automation

The integration of data analytics and artificial intelligence (AI) has taken automation to new heights:

Real-Time Insights

Embedded sensors collect critical data on operational variables like temperature and equipment performance. This data is used to optimize processes and minimize waste.

Predictive Maintenance

AI-powered systems analyze equipment data to predict failures before they occur. For example, vibration sensors on machinery detect wear and tear early, ensuring timely repairs.

AI-Driven Optimization

AI algorithms provide actionable insights to improve workflows, allocate resources efficiently, and forecast production demands, helping manufacturers stay ahead in a competitive market.

Key Benefits of Automation in Heavy Industries

Increased Productivity: Automation allows for continuous operation with minimal oversight, dramatically boosting production output.

Cost Savings: Reduced labor, energy consumption, and maintenance needs lead to significant long-term savings.

Sustainability: Energy-efficient systems and optimized processes reduce emissions, aligning with global sustainability efforts.

Future of Automation in Steel and Foundries

Emerging trends include autonomous material transport systems, AI-powered robotics, and advanced Industry 4.0 integrations. These innovations promise even safer, more efficient, and environmentally friendly operations in the future.

LeisterTech: Innovating Heavy Industry Automation

LeisterTech leads the way in providing advanced automation solutions for steel production and foundries. Their state-of-the-art machinery, such as hot billet shearing machines, hydraulic pushers, and lifting magnets, is designed to enhance operational efficiency and safety. Partnering with LeisterTech ensures manufacturers stay competitive in an evolving industrial landscape.

Automation is no longer a luxury—it is a necessity for the future of steel production and foundries. By adopting these technologies, industries can achieve smarter, safer, and more sustainable operations.

#Automation #SteelProduction #FoundrySafety #IndustrialInnovation #SmartTechnologies #EnergyOptimization #HeavyIndustry #LeisterTech #ManufacturingSolutions #SustainableIndustry